4 Flush Joint Casing Specs

Posted on by admin

4 Flush Joint Casing Specs Rating: 4,4/5 3728 votes

Titan's flush threaded thermoplastic pipe provides a smooth inner and outer joint surface of the assembled pipe. Flush threads are cut on 'state of the art' CNC machinery and are subject to Titan's stringent quality control.

Titan provide flush joint threads that conform to ASTM F480 Standard Specification for thermoplastic well casing pipe and couplings, made in standard dimension ratios (SDR), schedule 40 and schedule 80 or custom cut threads to suit a specific need.

The PVC flush threaded casing pipe and screen shall be manufactured from Type 1, Grade 1 resins as specified in ASTM D1785. The casing pipe shall also meet ASTM D2665.

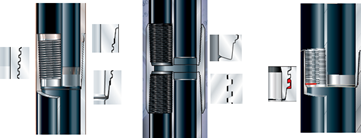

To assure easy make up, the PVC monitor pipe and screen must be threaded to the ASTM F480-90 specification with O-ring groove turned in the male thread.

Titan maintains an extensive inventory of flush joint threaded PVC well casing and screen used for groundwater monitoring, remediation and dewatering.

O-ring seals are available in Buna or Viton. Screens and casings can be shipped in skids or provided washed with alconox detergent, individually bagged and packaged in wax coated heavy duty boxes.

Titan provide flush joint threads that conform to ASTM F480 Standard Specification for thermoplastic well casing pipe and couplings, made in standard dimension ratios (SDR), schedule 40 and schedule 80 or custom cut threads to suit a specific need.

The PVC flush threaded casing pipe and screen shall be manufactured from Type 1, Grade 1 resins as specified in ASTM D1785. The casing pipe shall also meet ASTM D2665.

To assure easy make up, the PVC monitor pipe and screen must be threaded to the ASTM F480-90 specification with O-ring groove turned in the male thread.

Titan maintains an extensive inventory of flush joint threaded PVC well casing and screen used for groundwater monitoring, remediation and dewatering.

O-ring seals are available in Buna or Viton. Screens and casings can be shipped in skids or provided washed with alconox detergent, individually bagged and packaged in wax coated heavy duty boxes.

Casing Specs Chart

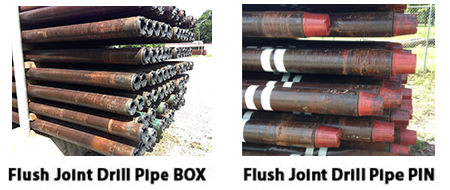

True Flush Joint connections are designed to ensure that the connections’ outside diameter and inside diameter are the same as the original tubular. Used predominantly in special clearance applications like liners, the flush joint connection exhibits strengths of 30% – 60% of the pipe body.

5.5 Casing Specs

13 3 8 Casing Specs

- VAM® Connection Selection Guide. VAM ® has been the leading brand of premium connections in the oil and gas industry for over 50 years. Each year VAM ® designs new connections, extends product lines and qualifies new sizes to the most stringent specifications to meet our customer needs.

- For 4-1/2, 5, and 5-1/2 casing couplings, the outer diameter and wall thickness are increased. Therefore, the calculation of the material weight increase or decrease has been updated respectively. The 9th edition requires the outer diameter of the coupling to be 127mm, 141.3Omm, and 153.67mm respectively.